The instrument offers a high-capacity automated solution, ideally suited to meet the precise and rigorous requirements of both development and production quality control environments. The 100X is perfect for testing particle filters, filtering half-mask particles, powered air for masks/half masks, and powered hoods/helmets.

Aerosol Generation and Flow Control

The 100X aerosol generator produces a specific size and concentration of oil or salt aerosol particles. The 100X measures and verifies the particle concentration at the flow rate set by the user.

Filter Sample Placement

A filter is placed in the test fixture to begin the test. Test samples can be placed by a human operator (manual applications) or a robotic arm (auto/on-line applications).

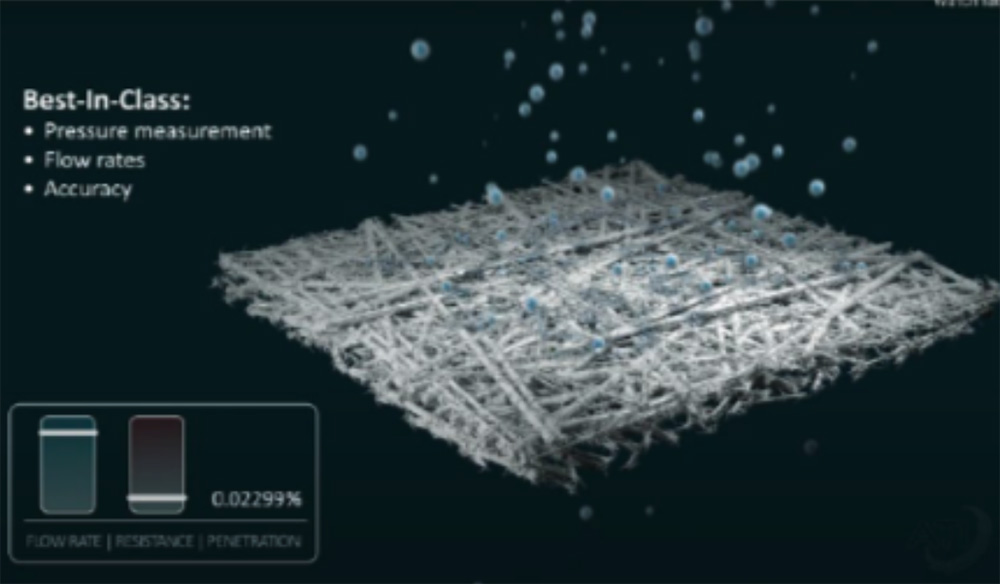

Filter Efficiency and Resistance Measurements

The 100X’s photometer measures the mass of the particles that pass through the filter to calculate efficiency. Similarly, the pressure transducers measure differential pressure to determine resistance.

The 100X meets global industrial standards:

- EN 13274-7:2019 Paraffin Test

- EN 12941/EN 12942

- EN 143/EN 149

- ASTM F3502-21: Barrier Face Covering

- ASTM F2100-23: Medical Face Mask

Delivering Best-in-Class Performance and Low Cost of Ownership

The 100X is a highly accurate, flexible test rig for a wide range of filter media types designed to optimize production yields while delivering the lowest cost of ownership.

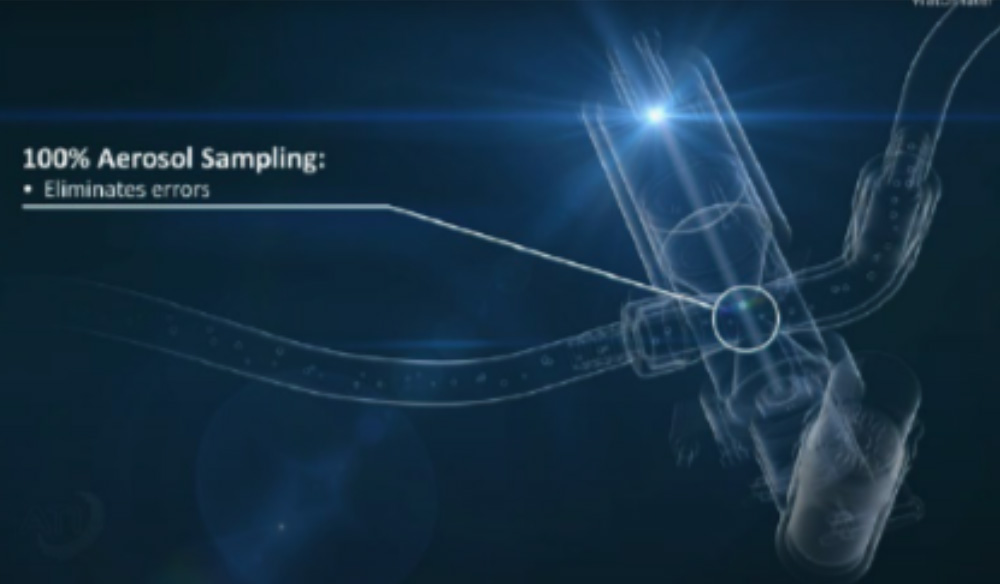

100% Sampling Aerosol Detection System

The 100% Sampling Aerosol Detection System is capable of testing a wide range of HEPA and ULPA filters, up to 99.9995% efficiency. Its innovative design provides a single source of truth, reduces potential sampling errors inherent in legacy designs and with fewer, more robust parts, reduces serviceability costs while increasing equipment uptime.

Best-in-Class Differential Pressure Management Accuracy

The 100X can be configured with your choice of four differential pressure measurement ranges, providing highly accurate, repeatable results that minimize false failures, while increasing both production yields and confidence in the test results.

Automatic, Hybrid & Manual Configurations

The 100X can be configured at time of order to operate three ways:

- The Manual version is ideal for lab use or production lot testing that requires the operator to initiate the test using ergonomic photoelectric actuators. A test fixture for 100 cm2 flat sheet media is included.

- The Automatic version integrates seamlessly with a customer designed, PLC-driven, automated production line and is ideal for 100% in-line non-destructive product testing. The unit is controlled via communication ports and becomes a client device to the automated production line.

- The Hybrid version provides the versatility to operate in Manual mode using the local test fixture or can be switched to Automatic mode using a remote fixture in an automated production environment.

Wide Range of Aerosol Flow Rates

The 100X is capable of air flow rates between 10-170 lpm, providing flexibility to test a wide range of filter types. Integrated flow controller keeps flow rates constant leading to more accurate results. The 100X EN 13274 High Flow option provides aerosol output up to 170 lpm and can be used to test PAPR filters or to optimize production throughput by testing two or more filter cartridges at once in a fully automated production line.

Oil or Salt Aerosol Generation

The 100X is available in either an Oil (DOP, PAO, Paraffin) or Salt (NaCl) aerosol generation models. The patented Aerosol Solution Replenishment System is a separate 2-liter reservoir tank that increases productivity by eliminating the need to shut down production to refill the generator. For salt-based test systems, the replenishment system mitigates aerosol concentration and size / distribution shifts due to dynamic salinity.

- Measure filter efficiency up to 99.9995%

- Quiet – ideal for QC and R&D labs